Our company has specialised in the development and production of components for use under the most demanding conditions.

We use our know-how in the most modern development and manufacturing techniques to optimise the components to be developed in every discipline.

Our development competences are divided into two areas:

Engineering.

Development of new ideas, concepts and components

Reverse Engineering.

Re-modelling and further development of already existing components

Engineering.

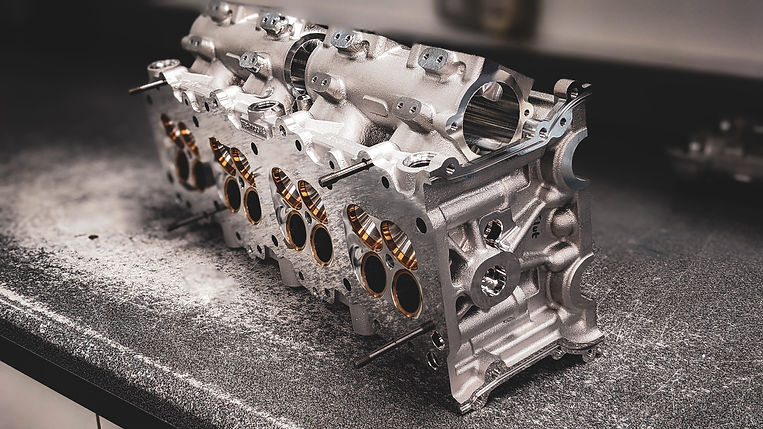

Our engineering includes planning, CAD design, FEM simulation, manufacturing and assembly. Our speciality lies in developing new high-tech components that make your vehicle capable of winning.

In addition, we further develop existing components to create components that are optimised for motorsports.

Planning

Design

Simulation

Manufacturing

Assembly

In accordance with our company philosophy, we offer you a high vertical range of manufacture from the production of individual parts to the production of small series.

In addition to our own production, we have a diverse and international partner network and can offer you a solution for almost any challenge.

The following processes are used for the production of our components.

3D Scanning

3D Printing

GFRP / CFRP

Welding

Sheet Metal Work

Machining

Casting

Forging

Reverse Engineering.

In contrast to the development of new concepts and components, reverse engineering starts with an already existing component.

This methodology is always necessary when components are to be manufactured but no drawings or CAD models exist.

The reverse engineering of components into CAD models is done either by modern measuring methods or by 3D scanning. The 3D models generated in this way can either be used for direct production or as a starting point for optimising the component.

Our entire technical and industry-specific know-how flows into the implementation of the optimisation and production.

In this way, spare parts that are no longer available can be reproduced or optimised, for example for vintage cars or historic motor sports.

Step 1: Initial component

Step 2: CAD- model

Step 3: Prototype

Step 4: Functional part

-

The initial component is usually physically present

-

Component is measured or 3D scanned

-

Individual parts or entire assemblies can be reconstructed

-

Reconstruction based on images is also possible

-

The measurement data is transferred to a CAD system

-

The components are modelled in detail in the CAD system

-

Optimisation takes place with regard to the component properties and manufacturability

-

If necessary, the component is subjected to a strength and stiffness simulation.

-

A prototype is produced, usually with the help of rapid prototyping (e.g. 3D printing)

-

Through the prototype, the design can be checked and the assembly tested

-

In some cases, the prototype can also be used to test the functions

-

If necessary, the CAD model is subjected to an optimisation loop

-

By conscientiously carrying out the preceding steps, a defect-free functional part can be manufactured

-

The functionality and durability of the component are extensively tested

-

The components are delivered ready for installation and, if necessary, pre-assembled